Industrial ultrasonic cleaner

Industrial ultrasonic cleaners include single tank, multi-tank, and other forms of cleaners. It contains many customized features such as heating, timing, filtration and many other customized features.

Single-Tank Ultrasonic Cleaner

Technical Specifications

- Capacity: 88L-960L (standard model) or customizable (e.g., 290×200×220mm)

- Frequency: 28kHz with temperature control (ambient to 100°C)

- Material: SUS304 stainless steel, acid/alkali-resistant

Features & Advantages

- Compact design for small-batch cleaning 1.

- Compatible with aqueous or solvent-based solutions for degreasing, derusting, and dewaxing.

- Typical applications: Hardware components, PCBs, eyewear frames, and medical instruments.

Dual-Tank Ultrasonic Cleaner

- Dimensions: 3000×1200×1300mm (large-scale models)

- Functions: Ultrasonic cleaning + rinsing + hot air drying

- Add-ons: Oil-water separator, filtration system

Features & Advantages

- Dedicated tanks for contamination removal and post-rinsing to prevent cross-contamination 3.

- Ideal for intricate parts (e.g., fuel filters, watch components) and precision cleaning (semiconductor chips, optical devices).

- Key industries: Marine fittings, automotive parts, electroplating pretreatment.

Multi-Tank Ultrasonic Cleaner

Technical Specifications

- Configuration: 3-5 tanks (standard: cleaning-rinsing-drying)

- Customization: Non-standard processes (e.g., cleaning + filtration + passivation)

Features & Advantages

- Multi-stage processing for high-purity requirements (e.g., new energy batteries, semiconductor wafers) 2.

- Modular design supports extended workflows (e.g., pure water rinsing, anti-corrosion treatment).

- Applications: Post-electroplating treatment, 3D-printed part cleaning, aerospace components.

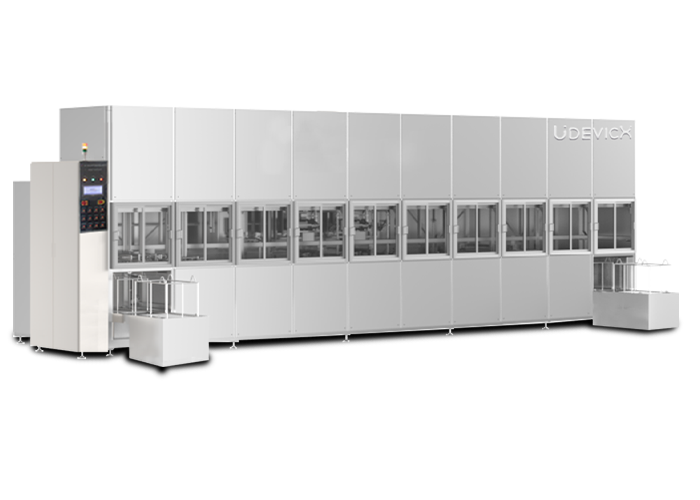

Fully Automated Ultrasonic Cleaning Line

Technical Specifications

- Automation: PLC-controlled with robotic arms and conveyor systems

- Capacity: 24/7 operation, compatible with vacuum hydrocarbon cleaning

Features & Advantages

- Integrated cleaning-drying-sorting processes for mass production (automotive, rail transport) 1.

- Ensures consistency in high-volume tasks (e.g., motor rotor housings, battery casings).

- Key implementations: Semiconductor wafer lines, photovoltaic module pretreatment.