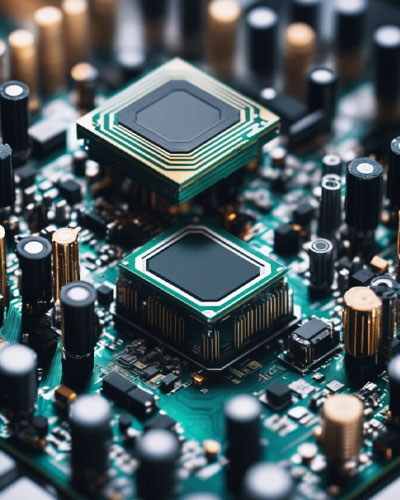

Precision clean parts made for the semiconductors equipment industry.

Ultrasonic semiconductors Device Parts Cleaning

Semiconductors professionals will encounter many needs for a Udevicx Ultrasonics precision cleaning equipment and Udevicx ultrasonic solutions.

Semiconductor cleaning faces a critical challenge in balancing precision and cost efficiency: As processes advance below 10nm nodes, traditional wet cleaning (e.g., RCA methods) struggles to remove 1nm-scale contaminants without damaging 3D structures, driving adoption of non-contact techniques like liquid CO₂ snow and supercritical CO₂ with chemical additives. However, these innovations require extended R&D validation and costly imported equipment. Wet cleaning’s high consumable costs (>70$/wafer per cycle) can be reduced 30% via diluted chemistry, yet process recalibration risks remain. Meanwhile, eco-friendly alternatives like ozonated water increase reagent costs by 50% and demand auxiliary recycling systems. Future solutions hinge on atomic-scale cleaning breakthroughs, AI-optimized parameters, and scaled production to offset green technology expenses.

Semiconductors device manufacturing industry challenges

Semiconductors devices often face many unique challenges in their cleaning due to their precision, complexity, and specialization.

Semiconductor cleaning of the core pain points is difficult to completely remove nanoscale contaminants (such as 1nm particles easily lead to device failure), and wet cleaning of the high cost of consumables (a single over 500 yuan / piece) and environmental protection cleaning agent cost surge (such as ozone water is 50% more expensive), superimposed on the dependence on imported equipment and process validation of the cycle is long (2-3 years) to push up the overall cost.

- Environmental protection and cost balance

- Risk of damage to precision devices during the cleaning process active residues

- Inadequate cleaning of micro- and nanostructures by conventional cleaning techniques

Advantages of Ultrasonic Cleaning

Ultrasonic cleaning has significant advantages

1.High Efficiency and Thoroughness

Ultrasonic cleaners generate high-frequency vibrations that produce microscopic bubbles, whose implosion creates impactful forces capable of penetrating microscopic gaps and uneven surfaces, ensuring thorough contamination removal.

2.Safety and Environmental Friendliness

Utilizing a physical cleaning mechanism, ultrasonic cleaning eliminates the need for harsh chemicals, preventing chemical pollution and corrosion while maintaining low noise levels and human safety.

3.Non-Destructive Performance

The gentle cavitation effect ensures minimal surface damage, making it ideal for precision components like semiconductor devices and fragile electronic parts.

4.Operational Flexibility

Rapid cleaning cycles significantly reduce processing time, minimizing rework and scrap rates, thereby optimizing production efficiency and cost-effectiveness.

5.Precision Control and Automation

Adjustable frequency and power enable tailored cleaning for varied materials and geometries, while seamless integration with automated production lines ensures intelligent, consistent outcomes.

6.Broad Application Scope

Widely employed in semiconductor manufacturing—including wafer pretreatment, post-etching cleaning, and encapsulation processes—ultrasonic technology addresses multifaceted industrial demands.

Udevicx solve your problems

Udevicx Equipment Series

Single Tank Ultrasonic Cleaner

Larger capacity, faster cleaning, rich features, precision cleaning, everything you want.

Benchtop ultrasonic cleaner

The small size contains a lot of power, the cleaning ability is still strong, precision cleaning is not a problem.

Immersible Transducer

The level of customizability is high, with cleaning solutions tailored to your needs..