Udevicx™ Ultrasonic Parts & Accessories

Ultrasonic accessories mainly include transducer generators and other accessories. The HG6 and HG9 series focus on industrial-grade ultrasonic cleaning with multi-frequency adaptability. The HG6 (600-3000W, 25/28/40kHz) excels in heavy-duty applications like automotive part degreasing through its expandable power modules and fixed triple-frequency switching. The HG9 (600-2400W, adjustable 25/28/40kHz) enhances precision cleaning for medical instruments and semiconductors via intelligent frequency coordination and IoT-enabled compact design. The HL-2600 (600-3000W, 17-200kHz) extends frequency coverage to 200kHz for nanoscale contaminant removal in photovoltaic and electronic industries. The HL-900 (60/300/600W) serves laboratory and delicate cleaning scenarios with stepped power switching and energy-efficient operation. All models integrate smart power regulation and environmental adaptability for diverse industrial needs.

1.Ultrasonic Generator HG6 Series

Core Features

– Wide Power Range (600-3000W)

Supports stepless power adjustment with intelligent load matching, ideal for both laboratory-scale (600W) and heavy-duty industrial cleaning (3000W peak) .

– Triple-Frequency Fixed Switching (25/28/40kHz)

– 25kHz: Effective for removing heavy oil/grease from metal surfaces;

– 40kHz: Minimizes cavitation damage to precision components .

– Modular Parallel Expansion

Compatible with multi-module parallel configurations (e.g., DCDC high-power modules ), enabling power output up to 6000W for continuous production .

Key Applications

– Heavy Industry Cleaning: Degreasing automotive engine parts, post-weld residue removal on solar panels (3000W required) ;

– Mass Production: Pre-treatment for electroplating, deburring metal parts (paired with continuous wave mode);

– General Equipment Integration: Laboratory glassware cleaning, ultrasonic welding systems .

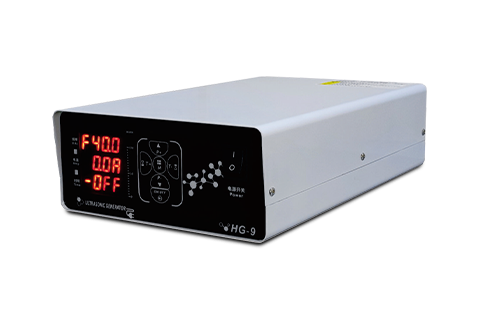

2. Ultrasonic Generator HG9 Series

Core Features

– Smart Triple-Frequency Coordination (25/28/40kHz Adjustable)

Enables single-frequency operation or dual-frequency alternating output (e.g., 25kHz+40kHz combined cleaning) for complex contaminant removal .

– Compact Energy-Efficient Design (600-2400W)

30% smaller footprint than HG6, with standby power ≤5W, compliant with medical equipment standards .

– IoT-Ready Connectivity

Optional Wi-Fi/Ethernet modules for remote parameter presets and energy monitoring (compatible with industrial PC hosts ).

Key Applications

– Medical Sector: Surgical instrument sterilization (40kHz + pulse mode), cell disruption in biolabs ;

– Precision Manufacturing: Optical lens coating pre-treatment, photoresist removal on semiconductor wafers (multi-frequency anti-damage);

– Smart Production Lines: Robotic cleaning stations (via universal interfaces for automation integration) .

3.Ultrasonic Generator HL-2600 Series

Core Features

– Ultra-Wide Frequency Range (17-200kHz)

Enables precise matching of cavitation effects for diverse materials, from delicate electronics (40-200kHz) to heavy industrial parts (17-28kHz) .

– High-Power Dynamic Control (600-3000W)

Supports intelligent load adaptation with ±2% power stability, suitable for 10L to 500L cleaning tanks .

– Multi-Mode Operation

Pulse/continuous wave switching reduces 30% energy consumption in batch processing .

Key Applications

– Automotive Manufacturing: Engine component degreasing (28kHz/2500W)

– Electronics Industry: PCB flux removal (80kHz pulsed mode)

– Aerospace: Titanium alloy surface treatment (17kHz high-power mode)

4. Ultrasonic Generator HL-900 Series

Core Features

– Triple-Power Presets (60W/300W/600W)

One-touch switching optimizes energy use for small-scale applications (e.g., 60W for jewelry cleaning) .

– Compact Intelligent Control

30% smaller footprint than industrial models, with auto-frequency tracking to prevent transducer overload .

– Low-Noise Design

<55dB operation meets laboratory acoustic standards .

Key Applications

– Medical Devices: Endoscope disinfection (40kHz/300W pulsed mode)

– Jewelry Processing: Precious metal polishing (60W precision mode)

– Research Labs: Microfluidic chip cleaning (200kHz/600W short-pulse)

3.Ultrasonic Transducer HNQ Series

Broad Frequency Adaptability

Operates across 20-135kHz range, enabling precise matching for diverse applications (e.g., fine particle dispersion at 135kHz & industrial cleaning at 20kHz)Optimized Power Efficiency

Delivers 50-100W output with ≥92% electro-mechanical conversion efficiency, reducing energy loss in continuous operationsMulti-Configuration Compatibility

Supports bolt-clamped, sandwiched, and Langevin-type transducer designs for flexible system integrationEnhanced Durability

Features corrosion-resistant electrodes and high-temperature ceramics (up to 150°C), suitable for harsh chemical environmentsCross-Industry Applications

Widely adopted in medical nebulizers (40-120kHz), precision welding, and wastewater treatment cavitation systems